Chinese Professional Polyimide Taping Machine - Combined Taping Machine – Multi Conductors PengSheng

Chinese Professional Polyimide Taping Machine - Combined Taping Machine – Multi Conductors PengSheng Detail:

Main technical data

Single wire quantity: 2/3/4 (or customized)

Single wire area: 5 mm²—80mm²

Rotating speed: max. 1000 rpm

Line speed: max. 30 m/min.

Pitch accuracy: ±0.05 mm

Taping pitch: 4~40 mm, step less adjustable

Special Characteristics

-Servo drive for the taping head

-Rigid and modular structure design to eliminate vibration interaction

-Taping pitch and speed easy adjusted by touch screen

-PLC control and touch screen operation

Overview

Taping

Caterpillar

Take-up

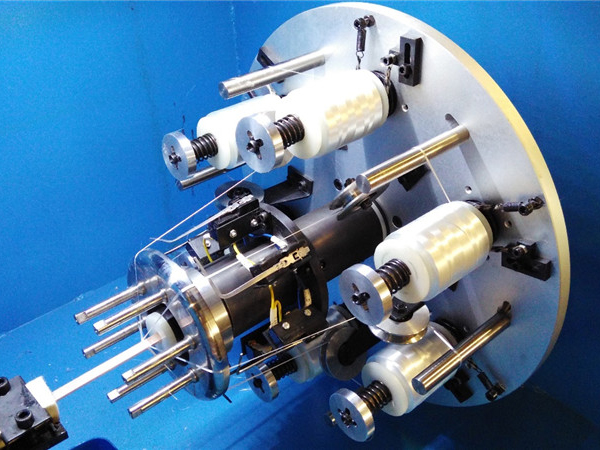

Product detail pictures:

Related Product Guide:

We offer wonderful energy in high-quality and improvement,merchandising,product sales and marketing and advertising and procedure for Chinese Professional Polyimide Taping Machine - Combined Taping Machine – Multi Conductors PengSheng , The product will supply to all over the world, such as: Maldives, Angola, Uruguay, After years of development, we have formed strong ability in new product development and strict quality control system to ensure excellent quality and service. With the support of many long term cooperated customers, our products are welcomed all over the world.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.

Write your message here and send it to us