Products

-

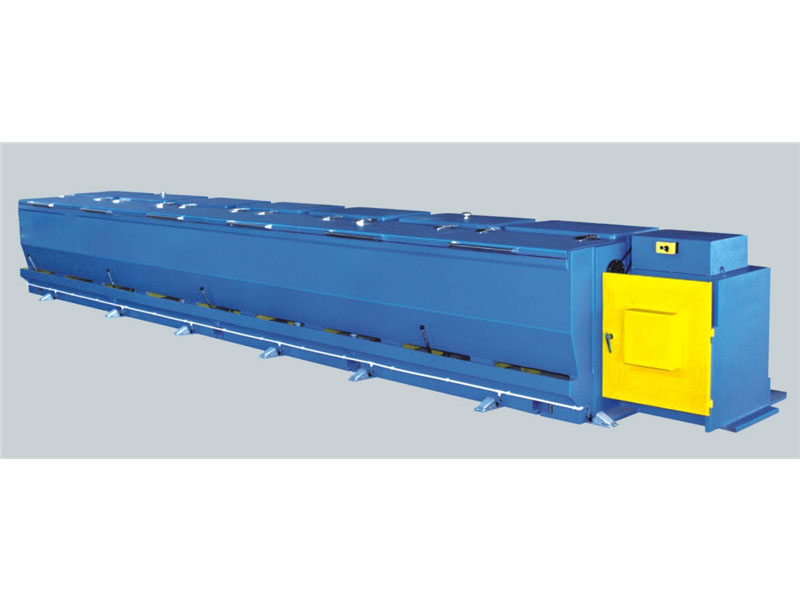

Automatic Continuous Copper Busbar Tin Plating Machine

OCTP 300/600 Copper Busbar Tin plating is matured and advanced continuous plating process line for busbar Tin plating with plating length range ≥3000 mm, width range 15 to 300 mm, thickness range 3-20 mm, and the speed range of 5~20 m/min.

-

Automatic Continuous Copper Busbar Silver Plating Machine

OCSP300 Copper Busbar Silver plating is matured and advanced continuous plating process line for busbar silver plating with plating length≥3000 mm, width 20 to 300 mm, thickness 3-20 mm, and the speed range of 5~18 m/min.

-

Up Casting system of Cu-OF Rod

The Up Casting system is mainly used to produce high quality oxygen free copper rod for wire and cable industries. With some special design, it is capable to make some copper alloys for various applications or some profiles like tubes and bus bar.

The system is with characters of high quality product, low investment, easy operation, low running cost, flexible in changing production size and no pollution to environment. -

Aluminum Continuous Casting And Rolling Line—Aluminum Rod CCR Line

Aluminum continuous casting and rolling line works to produce pure aluminum, 3000 series, 6000 series and 8000 series aluminum alloy rods in 9.5mm, 12mm and 15mm diameters.

The system is designed and supplied according to the processing material and related capacity.

The plant is composed of one set of four -wheel casting machine, drive unit, roller shearer, straightener and multi-frequency induction heater, rolling mill, rolling mill lubrication system, rolling mill emulsion system, rod cooling systems, coiler, and electrical control system. -

Copper continuous casting and rolling line—copper CCR line

-Five wheels casting machine with caster diameter of 2100mm or 1900mm and casting cross section area of 2300 sqmm

-2-Roll rolling process for the rough rolling and 3-Roll rolling process for the final rolling

-Rolling emulsion system, gear lubricating system, cooling system and other accessary equipments designed to work with the caster and rolling mill

-PLC program controlled operation from the caster to final coiler

-Coiling shape in orbital type programed; compact final coil obtained by hydraulic pressing device -

Rod Breakdown Machine with Individual Drives

• horizontal tandem design

• individual servo drive and control system

• Siemens reducer

• fully submerged cooling/emulsion system for long service life -

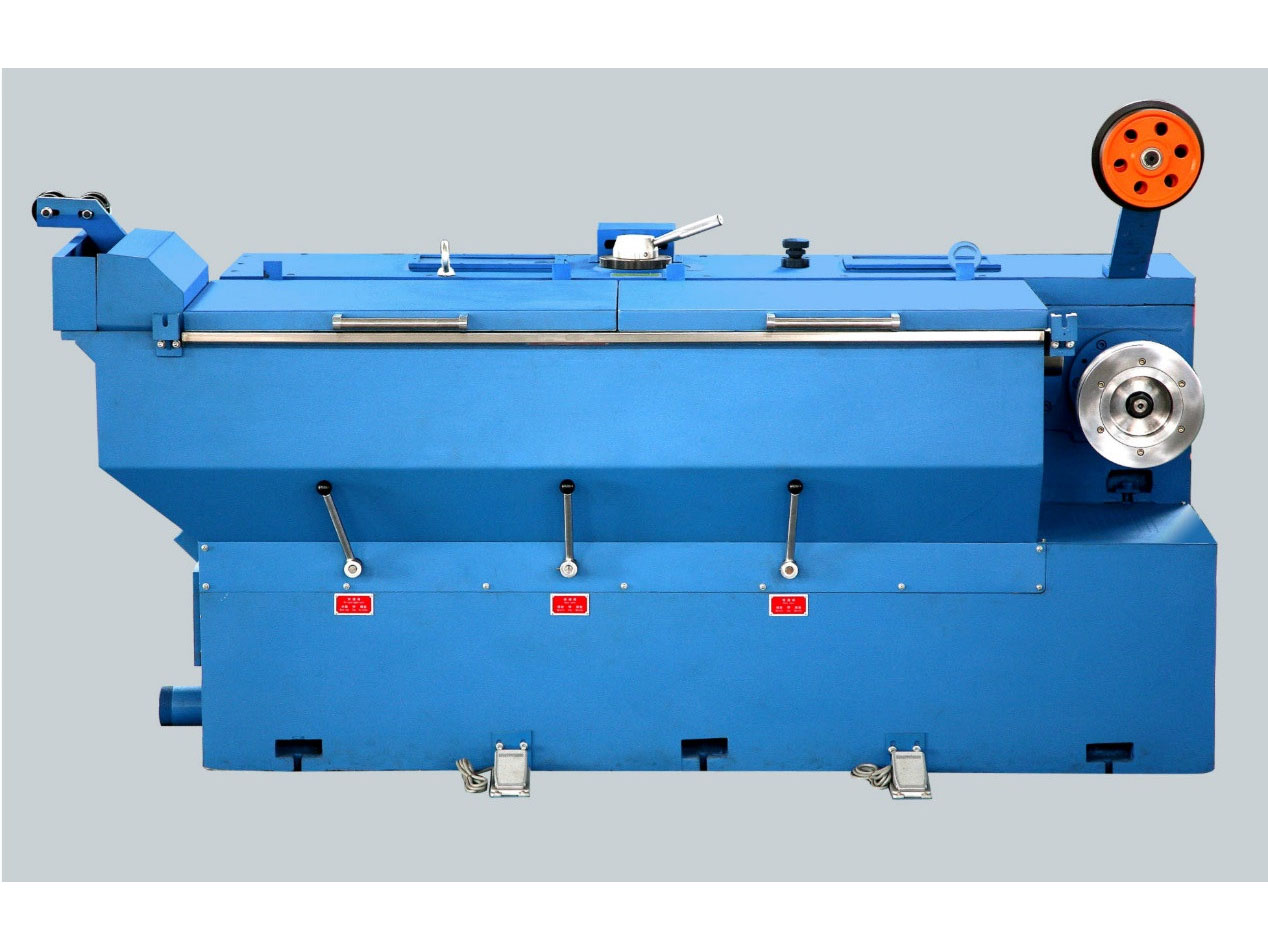

Copper/ Aluminum/ Alloy Rod Breakdown Machine

• horizontal tandem design

• force cooling/ lubrication to cycle gear oil of transmission

• helical precision gear made by 20CrMoTi material.

• fully submerged cooling/emulsion system for long service life

• mechanical seal design (it is composed of water dumping pan, oil dumping ring and labyrinth gland) to safeguard separation of drawing emulsion and gear oil. -

High-Efficiency Multi Wire Drawing Line

• compact design and reduced footprint

• force cooling/ lubrication to cycle gear oil of transmission

• helical precision gear and shaft made by 8Cr2Ni4WA material.

• mechanical seal design (it is composed of water dumping pan, oil dumping ring and labyrinth gland) to safeguard separation of drawing emulsion and gear oil. -

High-Efficiency Intermediate Drawing Machine

• cone pulley type design

• force cooling/ lubrication to cycle gear oil of transmission

• helical precision gear made by 20CrMoTi material.

• fully submerged cooling/emulsion system for long service life

• mechanical seal design to safeguard separation of drawing emulsion and gear oil. -

High-Efficiency Fine Wire Drawing Machine

Fine Wire Drawing Machine • transmitted by high quality flat belts, low noise. • double converter drive, constant tension control, energy saving • traverse by ball scre Type BD22/B16 B22 B24 Max inlet Ø [mm] 1.6 1.2 1.2 Outlet Ø range [mm] 0.15-0.6 0.1-0.32 0.08-0.32 No. of wires 1 1 1 No. of drafts 22/16 22 24 Max. speed [m/sec] 40 40 40 Wire elongation per draft 15%-18% 15%-18% 8%-13% Fine Wire Drawing Machine with High-Capacity Spooler • compact design for space saving •... -

Horizontal DC Resistance Annealer

• horizontal DC resistance annealer is suitable for rod breakdown machines and intermediate drawing machines

• digital annealing voltage control for wire with consistent quality

• 2-3 zone annealing system

• nitrogen or steam protection system for preventing oxidization

• ergonomic and user-friendly machine design for easy maintenance -

Vertical DC Resistance Annealer

• vertical DC resistance annealer for intermediate drawing machines

• digital annealing voltage control for wire with consistent quality

• 3-zone annealing system

• nitrogen or steam protection system for preventing oxidization

• ergonomic and user-friendly design for easy maintenance