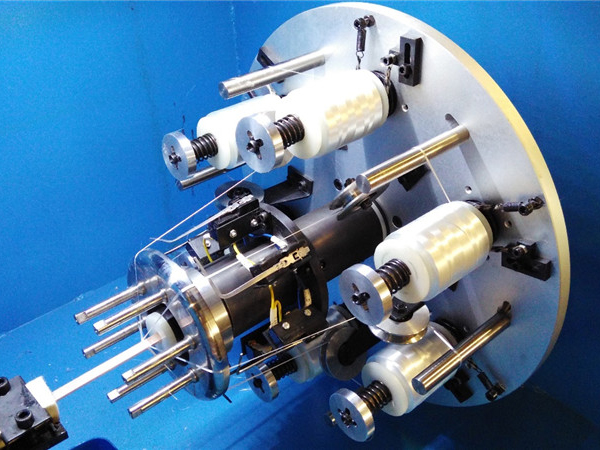

Good Quality Paper Taping Machine And Insulating Machine - Fiber Glass Insulating Machine PengSheng

Good Quality Paper Taping Machine And Insulating Machine - Fiber Glass Insulating Machine PengSheng Detail:

Main technical data

Round conductor diameter: 2.5mm—6.0mm

Flat conductor area: 5mm²—80 mm²(Width: 4mm-16mm, Thickness: 0.8mm-5.0mm)

Rotating speed: max. 800 rpm

Line speed: max. 8 m/min.

Special Characteristics

Servo drive for the winding head

Auto-stop when fiberglass broken

Rigid and modular structure design to eliminate vibration interaction

PLC control and touch screen operation

Overview

Taping

Oven

Product

Product detail pictures:

Related Product Guide:

Our products are greatly recognized and trustworthy by users and will fulfill continually shifting economic and social requires for Good Quality Paper Taping Machine And Insulating Machine - Fiber Glass Insulating Machine PengSheng , The product will supply to all over the world, such as: Sweden, Qatar, Hanover, We will continue to devote ourselves to market & product development and build a well-knit service to our customer to create a more prosperous future. Please contact us today to find out how we can work together.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!

Write your message here and send it to us