If you’re in the wire and cable manufacturing industry, you know that Single Twist Bunching Machine / Double Twist Bunching Machine are the backbone of producing high-quality conductors. But with terms like Single Twist Stranding Machine or Double Twist Stranding Machine, choosing the right equipment can feel overwhelming. Beijing Orient Pengsheng Tech CO., LTD will introduce the differences, applications, and technical advantages of these machines—so you can make an informed decision without the jargon overload.

Bunching vs. Stranding: It’s the Same Game

First things first: Bunching and stranding refer to the same core process—twisting multiple wires or cables into a unified structure. Whether you call it a “bunch” or a “strand,” the goal is identical: creating flexible, durable conductors for applications like power transmission, automotive wiring, or telecommunications.

As industry experts put it:

“Bunching/stranding machines are designed for twisting wires and cables to be a bunch or a strand. For different wire and cable structures, our different models of double twist bunching machine and single twist bunching machine support well for most kinds of needs.”

In short, your choice boils down to twist type (single vs. double) and machine design (cantilever vs. frame). Let’s dive deeper.

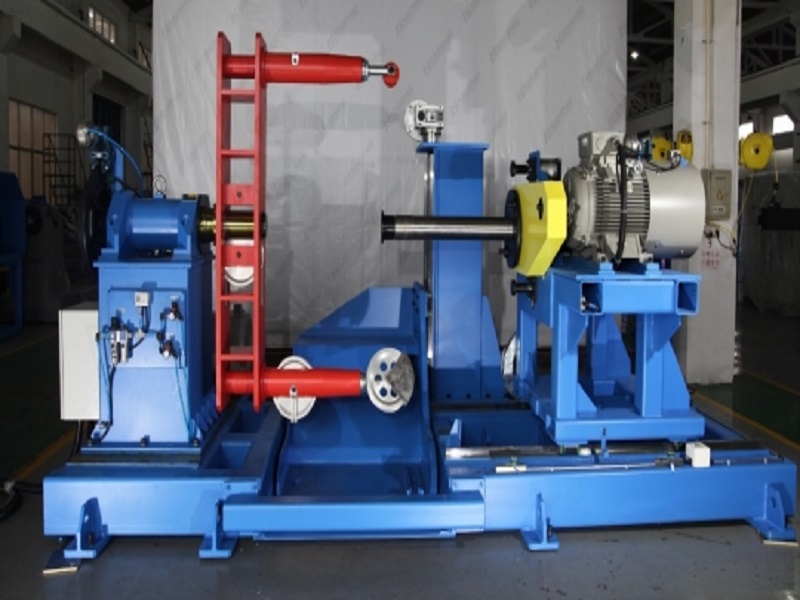

Double Twist Bunching Machine: Precision Meets Power

When efficiency and consistency are non-negotiable, double twist bunching machine shine. These machines perform two full twists per revolution, doubling productivity compared to single twist models. They’re ideal for high-volume production of fine-stranded cables (think robotics, EV wiring, or aerospace applications).

Key Features You’ll Love:

- Smart Controls: Modern double twist machines use AC drive technology, PLC systems, and HMI interfaces for precise speed, tension, and torque adjustments. No more guesswork—just smooth, repeatable results.

- Safety First: Think emergency stops, overload protection, and real-time fault diagnostics. These machines are built to protect both operators and your bottom line.

- Low Maintenance: With rugged designs and minimal wear parts, downtime becomes a rare headache.

As highlighted in our technical specs:

“For precision control and easy operation, AC technology, PLC & inverter control, and HMI are applied in our double twist bunching machine. Meanwhile, a variety of safety protections guarantee our machines run with high performance.”

Single Twist Stranding Machine: Flexibility for Heavy-Duty Jobs

Single twist Stranding machine perform one full twist per revolution, making them slower but more versatile for thicker cables or complex configurations. They’re the go-to for industrial power cables, overhead lines, or marine cabling where strength matters most.

We offer two single twist machine types to match your spool size:

- Cantilever Type

- Perfect for spools with diameters up to 1250 mm.

- Compact footprint, ideal for smaller facilities.

- Easy loading/unloading with its open-ended design.

2.Frame Type

- Handles massive spools from 1250 mm up to 2500 mm.

- Heavy-duty construction for extreme workloads.

- Stability-first design to prevent vibration during high-speed operation.

As specified:

“We produce two different kinds of single twist stranding machine:

• Cantilever type for spools from dia. 500 mm up to dia. 1250 mm

• Frame type for spools from dia. 1250 mm up to dia. 2500 mm.”

Double Twist vs. Single Twist: Which Should You Buy?

Still torn? Ask yourself these questions:

- What’s your production volume?

- Double twist = Faster output for thin wires.

- Single twist = Slower but better for thick, complex cables.

- What’s your cable diameter?

- Need to handle 2500 mm spools? Frame-type single twist is your hero.

- Do you prioritize automation?

- Double twist machines lead in PLC-driven automation for error-free runs.

- Budget constraints?

- Single twist machines (especially cantilever) often cost less upfront.

Pro Tips for Maximizing Machine Lifespan

- Lubrication Matters: Use high-temperature grease on twist heads.

- Tension Control: Uneven tension = uneven twists. Calibrate regularly.

- Spool Alignment: Misaligned spools cause friction and breaks.

Final Thoughts

Whether you opt for a double twist stranding machine with its smart tech or a rugged single twist stranding machine, the right choice depends on your cable specs, production goals, and facility setup. Need help deciding? Drop us a line—we’ve spent years fine-tuning these machines for industries like yours.

Ready to upgrade your wire production game? Explore our range of bunching/stranding machines today and see how precision engineering can transform your output!

Post time: May-09-2025