Featured Products

-

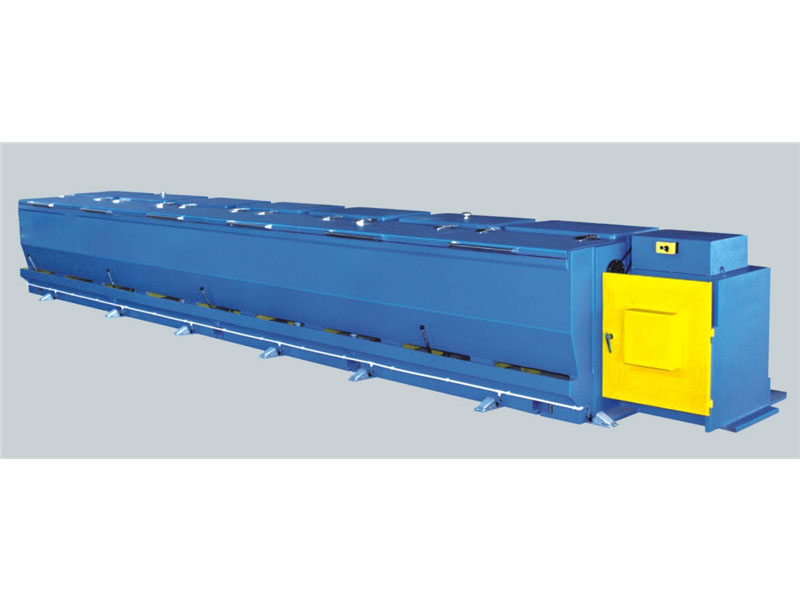

China Cheap Price Electric Wire Drawing Breakdown Machine for Aluminum Rod

• horizontal tandem design

• force cooling/ lubrication to cycle gear oil of transmission

• helical precision gear made by 20CrMoTi material.

• fully submerged cooling/emulsion system for long service life

• mechanical seal design (it is composed of water dumping pan, oil dumping ring and labyrinth gland) to safeguard separation of drawing emulsion and gear oil. -

Reliable Supplier China up Brass Casting Machine 8mm Copper Rod Upcasting Production Line

The Up Casting system is mainly used to produce high quality oxygen free copper rod for wire and cable industries. With some special design, it is capable to make some copper alloys for various applications or some profiles like tubes and bus bar.

The system is with characters of high quality product, low investment, easy operation, low running cost, flexible in changing production size and no pollution to environment. -

Good Quality China Upward Continuous Casting Line Oxygen Free Copper Rod 8mm Making Machine Wire Casting Plant

The Up Casting system is mainly used to produce high quality oxygen free copper rod for wire and cable industries. With some special design, it is capable to make some copper alloys for various applications or some profiles like tubes and bus bar.

The system is with characters of high quality product, low investment, easy operation, low running cost, flexible in changing production size and no pollution to environment. -

Factory Cheap Hot China Electrolytic Copper Continuous Casting and Rolling Production Line

-Five wheels casting machine with caster diameter of 2100mm or 1900mm and casting cross section area of 2300 sqmm

-2-Roll rolling process for the rough rolling and 3-Roll rolling process for the final rolling

-Rolling emulsion system, gear lubricating system, cooling system and other accessary equipments designed to work with the caster and rolling mill

-PLC program controlled operation from the caster to final coiler

-Coiling shape in orbital type programed; compact final coil obtained by hydraulic pressing device