Hey there! If you’re in the business of making copper rod – whether you’re starting fresh or looking to seriously upgrade your operation – you’ve probably heard the buzz about Copper Continuous Casting And Rolling Machine technology. And for good reason! Please let Beijing Orient Pengsheng Tech CO., LTD to introduce why a Copper Rod Continuous Casting And Rolling Machine (let’s call it the CCR Line for short) might be the game-changer you need, especially when you need top quality without reduce profit.

Think of the Copper Rod Continuous Casting and Rolling Machine as your all-in-one powerhouse. It takes raw copper – either pristine cathodes or various types of scrap – and transforms it directly into the high-quality rod wire that industries crave, all in one continuous, efficient flow. No more stop-start batch processes eating into your bottom line.

Raw Materials Made Easy: Flexibility is Key

One of the biggest headaches in copper rod production? Sourcing consistent, expensive raw material. The advantage of Copper Rod Continuous Casting And Rolling Machine setup is its flexibility:

- The Cathode Route: Got access to good copper cathodes? Great! Use a vertical melting furnace feeding into a tilted holding furnace. This combo feeds your Copper Rod CCR line perfectly, giving you incredibly consistent, high-purity ETP (Electrolytic Tough Pitch) rod, shift after shift. It’s smooth, it’s high-output, and the quality is rock-solid.

- The Scrap Champion: This is where things get really interesting economically. Want to use 100% copper scrap? Absolutely no problem with a well-designed reverberatory furnace feeding your Continuous Casting And Rolling Mill. Don’t worry if the scrap quality varies – these furnaces are built smart:

Increased thermal efficiency means lower fuel costs.

Long working life means less downtime and maintenance stress.

Easier slagging and refining keep the process smoothly.

Controlled final chemistry ensures the molten copper hitting your caster is accurately for producing FRHC (Fire Refined High Conductivity) rod that exceeds industry standards. Seriously, FRHC rod production by a Copper Rod CCR line is often the most attractive, evergreen solution globally for profitable copper recycling. You turn scrap into high-value product efficiently. Furnace capacities typically range from 40 to 150 tons per shift/day, fitting different production scales.

How the Magic Happens: The Copper Rod CCR Line Flow

So, how does copper go from molten metal to finished coil? It’s a beautifully synchronized process driven by modern PLC controls:

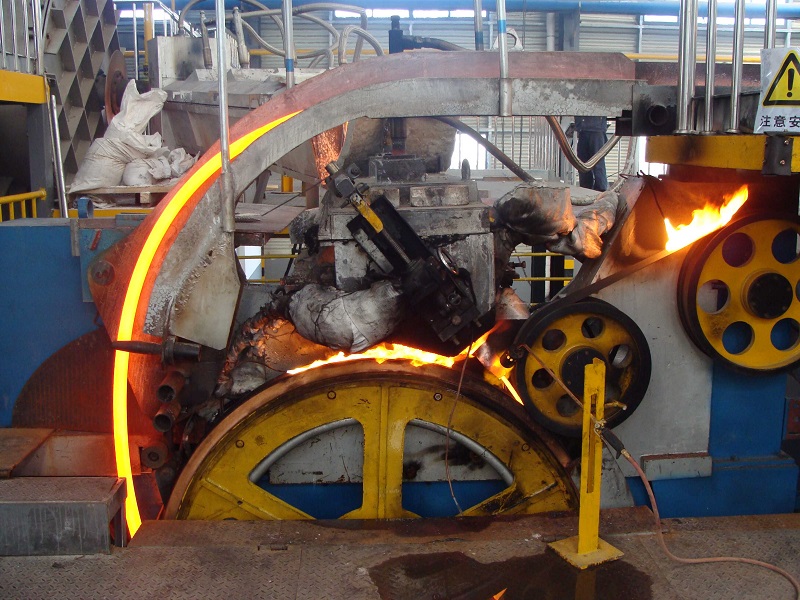

- Casting: The heart starts with the Continuous Casting And Rolling Machine. Think of a precision five wheels casting machine with caster diameter of 2100mm or 1900mm and casting cross section area of 2300 or 2400 sqmm. This robust setup ensures a stable, high-quality cast ingot enters the line.

- Prepare Work: That cast ingot gets quickly trimmed by a roller shearer, straightened out, and any rough edges smoothed off by a deburring unit.

- Rolling Time: The prepared ingot is feed into the rolling mill. Key support systems like the rolling emulsion system, gear lubricating system, cooling system and other accessary equipment designed to work with the casting and rolling mill to keep everything running cool and smooth.

- Cooling Down: After rolling, the hot rod needs controlled cooling to lock in its properties.

- Perfect Coiling: Finally, the rod into the coiler. This isn’t just a normal coiler; it uses an orbital type programed method, and the result is a super compact final coil. Neat, tidy, easy to handle and ship. And remember, this entire journey – from the caster to final coiler – is seamlessly managed by PLC program controlled operation. Less operator stress, more consistent output.

Why Choose a Copper Rod Continuous Casting and Rolling Machine?

Let’s see really matters for your business:

- High Rate, Low Cost: Copper continuous casting and rolling technology is simply the most economical way to produce large capacity of copper rod consistently. Continuous Casting And Rolling Mill efficiency is unmatched by older methods.

- Quality You Can Trust: Whether producing ETP rod from cathodes or top-tier FRHC rod from scrap, the output from a modern Copper Rod Continuous Casting And Rolling Machine consistently exceeds reference standards. The precision 2-Roll/3-Roll rolling process is key here.

- Scrap = Profit: The ability to efficiently transform various copper scrap qualities into high-demand FRHC rod is a massive economic advantage. A well-run Copper Rod CCR line turns your scrap pile into a revenue stream.

- Serious Capacity: These aren’t small machines. Based on the furnace type and capacity, the line could have the yearly production big capacity.

- Long Service Life & Run Smooth: Components like the five wheels casting machine and the robust supporting systems (rolling emulsion system, gear lubricating system, cooling system…) are engineered for durability and reliability within the Continuous Casting And Rolling Machine.

You’re Not Just Buying a Machine, You’re Gaining a Partner

Let’s be real: a sophisticated Copper Rod Continuous Casting And Rolling Machine is a significant investment. The technical service for this system is critical for the client. That’s why the support doesn’t stop when the machine ships.

Besides the machine itself, we give technical service for the machine installation, running, training and daily maintain support. We understand that your success depends on the line running smoothly and profitably. With years of experience, we are capable to run the machine well with our customers to have their best business benefit. Think of us as your on-call experts, helping you optimize production, minimize downtime, and make the best profit for your Copper Rod CCR line.

Ready to Transform Your Copper Rod Production?

If you’re aiming for higher output, lower costs (especially using scrap!), consistent top quality (ETP or FRHC), and a reliable partner to support your business, the Copper Rod Continuous Casting And Rolling Machine is the best choice. Continuous Casting And Rolling Mill technology has revolutionized copper rod production, and it’s ready to do the same for your business. Forget the limitations of old batch processes. Step into the efficient, profitable world of continuous production with a high-efficient Copper Rod CCR line. Please contact Beijing Orient Pengsheng Tech CO., LTD can help you achieve your production goals!

Post time: Jul-03-2025